What is Kraft Paper?

Kraft Paper for pouches refers to a type of paper material specifically designed and used for the production of pouch packaging, the raw material is plant fiber.

It is a versatile and eco-friendly alternative to traditional plastic pouches and offers various advantages in terms of sustainability, branding, and product protection.

They may have limitations in terms of moisture resistance compared to plastic pouches.

Low lanimation and het sealing strength (widely used for light packaging)

Easy teat

Unique performance effect

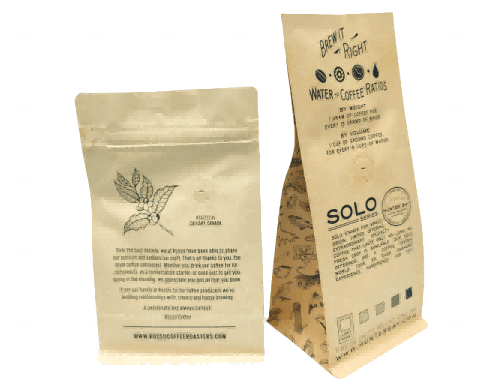

Kraft Paper Series

Printing directly then laminate the heat sealing layer

Used for lamination

Coated paper

High cost, suitable for fine priting

The Advantages of Kraft Paper for Flexible Packaging

Kraft paper, a material widely seen in our daily lives, is closely associated with our daily activities.

For example, pumpkin seed bags, nut bags, and freshly ground coffee bags.

Due to the trend of “anti-plastic,” kraft paper bags have become the preferred choice for companies, and many international brands have started using them for packaging.

What makes kraft paper so beloved by everyone?

- The most significant aspect is the strong environmental performance of kraft paper bags.

In the prevailing era of environmental protection, the non-toxic, odorless, zero-pollution, and recyclable nature of kraft paper has greatly enhanced its competitiveness.

- Environmentally Friendly: They are eco-friendly and recyclable, avoiding the generation of harmful chemical pollutants in the environment.

- Kraft paper exhibit strong printing capabilities.

With inherent color, kraft paper allows for artistic beauty in printing without the need for full-page printing, resulting in cost savings and reduced printing cycle time.

- Exceptional production and processing performance.

Compared to shrink film, kraft paper demonstrates stronger adaptability, along with certain buffering and impact resistance.The mechanical equipment for product manufacturing and processing performs well, with good buffering capabilities, facilitating composite production processes.

The Drawbacks of Kraft Paper

- If you want to print colorful and exquisite pattern designs, kraft paper bags may not achieve the desired results.

Due to the relatively non-smooth surface of kraft paper, there can be an uneven distribution of printing ink when applied to the surface of kraft paper.Therefore, compared to plastic packaging bags, the printing patterns on plastic packaging bags tend to be more delicate.

- Poor moisture and water resistance.

The key drawback of kraft paper bags is that they should not come into contact with water.When kraft paper gets wet, it becomes soft, and the entire kraft paper bag loses its structural integrity. The storage area for packaging bags needs to maintain natural ventilation and dryness, which poses a challenge for kraft paper bags.

Food packaging bags made of paper have poor moisture, and water resistance, are easy to be damp, and deform, not suitable for packaging long-term preservation of food, but for short-term preservation of food, kraft paper bag is still a better packaging material.

Paper Plastic Packaging

This not only presents a retro and high-end brand image but also reflects the company’s environmental awareness and responsibility.

- Paper//PE//AL//PE is a commonly used structure for packaging condiments, nuts, snacks, and more.

- White Paper//PE, White PE//PE//MPET//PE structure is typically used for single-serve sachets for sugar.

- Paper-plastic bags are most commonly employed for packaging coffee, whether it’s coffee beans or powder, making them highly noticeable on shelves.

The structure PET/White Kraft Paper/MPET/LLDPE is often chosen. - Chocolate often utilizes BOPP/Paper/MPET-cold seal paper plastic packaging film. On the other hand, ice cream adopts the structure AL//PE//white paper.

- Even the easily overlooked potato chip packaging film for sealing cans uses paper plastic packaging film, that is structure PET/white paper/PET/AL/PE.

- When paper bags are used for outer packaging, the high-end image of paper plastic is evident, with structures like Matte BOPP/Kraft Paper/PE commonly used.

- Paper-plastic packaging is also suitable for non-food products such as personal care and household items. The structure White Paper//PE/AL/SPE is an example.

Start With KDW

+86 13559233681(Wechat, Whatsapp)

No1, Anbian Rd, Torch High-Tech Zone (XiangAn), Xiamen, Fujian, China