Anti-Counterfeit Packaging:Everything You Need to Know

In this context, anti-counterfeiting packaging solutions have become the “preferred solution” for preventing economic losses, health risks, online fraud, and other crimes.

Globally, different types of anti-counterfeiting packaging, whether covert or public, are preventing vulnerable products from being counterfeited. They directly or indirectly protect brands and patients or consumers, saving lives and the economic well-being of consumers.

Advanced anti-counterfeit packaging technologies prevent counterfeiting replication and confirm the security of packaged goods when they reach end-users.

What is Anti-counterfeit Packaging?

Anti-counterfeit packaging refers to the techniques and methods employed through packaging to prevent intentional tampering and counterfeiting of goods from manufacturers to distributors, and ultimately to consumers.

The goal is to prevent goods from being replaced or counterfeited during circulation and transfer.

Anti-counterfeit packaging is mainly for sales packaging, i.e. the product packaging that needs to enter the market and be selected by consumers on shelves.

For bulk industrial product packaging and transportation packaging, the meaning of anti-counterfeit packaging is relatively less.

The Functions of Anti-counterfeit Packaging

Anti-counterfeit packaging serves to protect both the interests and reputation of product manufacturers and the well-being of consumers. It acts as a deterrent against the production of fake and substandard goods.

Scientific and reliable anti-counterfeit packaging promotes the application and adoption of new technologies, processes, and business concepts in product development, production, and enhancement.

It provides scientific validation for the authenticity of certain products and enhances trust and security for the packaged items.

- Protecting the interests and business of product manufacturers, safeguarding the interests and well-being of consumers

- Curbing the production of counterfeit goods.

- Promoting the application and dissemination of new packaging technologies, materials, processes, and innovative sales management awareness.

- Providing scientific verification of the authenticity of products.

- Enhancing the credibility and sense of security of goods.

Features of Anti-counterfeiting packaging

Anti-counterfeiting packaging is an extension and advancement of conventional packaging.

- Its primary feature is to protect products from intentional harm and damage through certain covert means.

- Sometimes anti-counterfeit packaging looks no different from general packaging at first glance – its security features only display the anti-counterfeiting functions under specific conditions.

- Anti-counterfeit packaging achieves multiple functions and conveys a large amount of information.

- The production, design, and utilization of anti-counterfeit packaging are more scientific, and challenging, and require careful methods and techniques.

Classification of anti-counterfeiting packaging

- Classified by authentication methods:

- Primary anti-counterfeiting packaging refers to mass identification methods, where authenticity can be determined through simple means or without the need for any special technology.

- Secondary anti-counterfeiting packaging requires professional personnel or specialized instruments for identification, incorporating special materials and information through specific processes.

- Composite anti-counterfeiting packaging combines the above two anti-counterfeiting packaging technologies to facilitate identification by general consumers while also allowing for scientific verification through equipment.

- Classified by packaging types:

- Internal anti-counterfeit packaging involves applying anti-counterfeit technology to the internal packaging.

- External anti-counterfeit packaging involves applying anti-counterfeit technology to the external packaging.

- Label-based anti-counterfeit packaging utilizes specially treated labels placed inside or affixed to the packaging.

Anti-Counterfeit Packaging Solutions

Anti-counterfeit packaging methods are diverse and constantly evolving. Based on different technological levels and methods, they can be broadly categorized as follows:

- Adoption of Anti-counterfeit Identification.

- Utilization of Specialized Materials and Processes.

- Application of Printing Technology.

- Incorporation of Packaging Structural Forms, and more.

The choice of anti-counterfeit technology should depend on the attributes and value of the product. Based on the analysis of the positioning of anti-counterfeit packaging, a single or multiple anti-counterfeit technologies can be employed.

In any case, simplicity, practicality, effectiveness, and cost-effectiveness are essential principles in selecting anti-counterfeit packaging methods.

Laser Anti-Counterfeiting Identification

- Laser Holographic Images

Laser holographic image identification is a representative anti-counterfeit packaging technology and is currently the most popular means of counterfeiting prevention.Laser holographic images integrate the latest achievements in disciplines such as laser technology, precision mechanics, and physical chemistry, making their technological content relatively high.Qualified holographic embossed images require collaboration between graphic design skills, specialized technicians, and a dedicated holographic technology environment.

For most small-scale counterfeiters, the high technical content of laser holographic symbols makes it challenging to master the entire manufacturing process and acquire the necessary equipment.

The production process of laser holographic anti-counterfeit trademarks involves pattern selection and design, holographic image capture, holographic master plate creation, metal template production, embossing, lamination, die-cutting, and final product assembly.

Laser-embossed holographic images are characterized by their low cost, ease of verification, and peculiar optical effects, making them widely used in anti-counterfeit packaging.

Many manufacturers worldwide modify the conventional approach of using small laser holographic symbols for localized anti-counterfeiting by treating the entire packaging with laser technology, creating a large-area three-dimensional anti-counterfeit effect that confounds counterfeiters.

- Laser Anti-counterfeiting Packaging Structures:

- Flexible Packaging: Used for packaging candies, food, beverages, tea, medicines, cosmetics, etc.

It is made with high-tech technology to produce laser films, which are then combined with ordinary plastic films and printed to form laser material flexible packaging bags. - Rigid Packaging Box: Used for packaging alcoholic beverages, medicines, health foods, toothpaste, soap, cosmetics, etc.

One type involves creating laser films with high-tech technology, combining them with cardboard, and printing to form rigid boxes.

Another type involves printing on rigid boxes and then combining them with laser-treated glossy films, forming glossy-type rigid boxes.

- Handbag: Used for packaging suits, coats, medicines, food, etc.

- Laser Paper: Used for packaging cigarette boxes, bottle labels, tags, tax strips, gift packs, etc.

It is directly laser-treated on paper. Its production process is challenging and costly, but due to its excellent printing performance and ease of handling, it is particularly suitable for making food boxes, gift packs, etc. - A type of PVC material with a thickness of 200-500μm that, after molding, forms laser material.

This material, when exposed to light, displays a splendid, colorful, and ever-changing laser holographic image. It not only has an exquisite appearance but also adopts special methods, making it difficult for counterfeiters to replicate.

This material can be used for various food packaging boxes and serves as transparent packaging boxes for stationery, office supplies, handicrafts, daily necessities, high-end clothing, etc.

- Flexible Packaging: Used for packaging candies, food, beverages, tea, medicines, cosmetics, etc.

Invisible Identification Systems

- Special functional anti-counterfeiting inks comprise four major types: photochromic ink, magnetic ink, fluorescent ink, and phosphorescent ink.

- Computer-generated holograms, computer-generated password patterns, computer optical pattern systems, etc., form codes that are not easily deciphered, providing strong anti-counterfeiting properties.

- Adding biological antibodies to products is a novel invisible identification system developed by the American BioCode company.

This system includes two substances: one is a symbolic compound added to the product, and the other is antibodies used for identifying the presence of the symbol and conducting quantitative analysis.

Laser Coding

Laser coding is primarily used for printing production dates and product batch numbers on packaging. Laser coding technology is also known as laser “burning” technology.

Laser coding sealing technology is a preferable container anti-counterfeiting technique. After the product is filled and sealed, laser printing is applied at the seam between the lid and the container, with the upper part of the characters printed on the lid and the lower part on the container.

When packaging containers are reused, aligning the residual characters on new lids with those on old containers becomes challenging.

Moreover, laser equipment is expensive, and the coding is done on the production line. Counterfeiters find it difficult to invest heavily in purchasing such equipment, hence it is referred to as investment-type anti-counterfeiting packaging design.

During coding, manufacturers can freely change the printing template, using different templates for various dates. The secrecy of template changes adds to the difficulty of decoding by outsiders.

In terms of anti-counterfeiting effectiveness, laser coding technology is not inferior to laser holographic imaging technology.

Laser holographic symbols are printed by printing factories, and the manufacturers using these symbols cannot ensure that the masterplate does not leak or get illegally duplicated from the printing stage.

Laser coding machines are expensive, and require online usage, and the concealed nature of template changes makes it challenging for small and medium-sized factories to engage in counterfeiting.

Special Packaging Structures

Disposable packaging containers, also known as destructive anti-counterfeiting packaging, can achieve anti-counterfeiting by becoming unusable once opened, preventing the reuse and counterfeiting known as “putting new wine in old bottles.”

The widespread use of anti-theft opening packaging in food and beverages also serves as a certain anti-counterfeiting measure, preventing product tampering and adulteration.

Currently, beverage caps, mineral water, and bottled xylitol often adopt visible anti-theft opening packaging. After the cap is opened, it cannot be restored, allowing consumers to determine whether the product has been tampered with.

Some containers can be designed with complexity or incorporate proprietary technologies from product manufacturing enterprises into the container structure and manufacturing processes. This makes it challenging for counterfeiters to imitate.

Development Trends of Anti-counterfeiting Packaging

As for modern anti-counterfeiting packaging, the overall development trend is towards high security and reliability, coupled with easy and convenient identification.

Security and reliability entail the use of anti-counterfeiting packaging technologies with high technical content and significant process difficulty. Moreover, these technologies should have low visibility, preferably being proprietary and exclusive.

Convenience in identification refers to simple and fast methods for distinguishing authenticity. This is especially crucial for general consumers; ideally, it should not require any instruments or tools for identification.

If tools are necessary, they should be specially designed and provided with the packaging.

Alternatively, identification can rely on human instincts (such as sight, hearing, touch, and smell) or specialized instruments and equipment for verification and judgment.

Development directions for anti-counterfeiting packaging include:

- Widely used and popularized anti-counterfeiting technologies will be replaced by new proprietary anti-counterfeiting packaging technologies.

- Every anti-counterfeiting packaging technology will eventually be supplanted by new methods after a certain period. No single anti-counterfeiting packaging technology is permanent or absolutely reliable.

Similar to currency, which continuously updates its anti-counterfeiting measures and technologies, product packaging should undergo a similar evolution. - With the growing awareness of anti-counterfeiting, different companies will utilize their independently developed technologies for packaging security

- The future of anti-counterfeiting packaging is heading towards a combination of “first-line anti-counterfeiting” and “second-line anti-counterfeiting.”

- Anti-counterfeiting packaging that integrates multiple technologies will continue to emerge. This is particularly advantageous for companies lacking expertise in anti-counterfeiting technologies.

Anti-counterfeiting Packaging at KDW

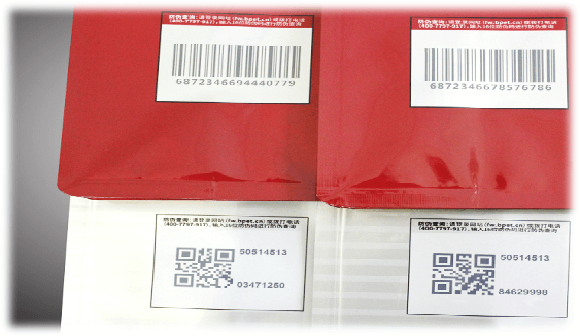

Flexible packaging widely uses laser coding for anti-counterfeit, promotion, quality control, and anti-channel conflict.

Kinderway Packaging has introduced an inkjet printer to provide services for customers in need of anti-counterfeiting printing.

- UV inkjet printing

UV inkjet printing in packaging utilizes ultraviolet (UV) curable inks in the inkjet printing process for creating designs, texts, or images on packaging materials.

This printing method has gained popularity in the packaging industry due to its several advantages.

- UV inkjet printing is versatile and can be applied to a variety of packaging substrates, including paper, cardboard, plastics, films, and foils. It adheres well to different materials, providing vibrant and high-quality prints.

- UV-cured inks result in durable prints that resist scratching, fading, and other forms of wear and tear. This durability is crucial for packaging applications, ensuring that the printed information remains intact throughout the product’s lifecycle.

This property makes it suitable for high-temperature retort pouches. - UV inkjet printing technology allows for variable data printing, making it suitable for personalized or serialized packaging, such as QR codes, barcodes, or unique identifiers.

- Laser Coding

Laser coding, also known as laser marking or laser engraving, is a technology used for creating marks, codes, or patterns on various materials using laser beams.

In the context of packaging, laser coding is often employed to apply alphanumeric codes, barcodes, QR codes, expiration dates, batch numbers, and other information directly onto the surface of packaging materials.- Laser coding is a non-contact process, meaning that there is no physical contact between the marking device and the material. This is advantageous for delicate or sensitive packaging materials, as it eliminates the risk of damage.

- Laser coding provides high precision and accuracy in marking. It allows for the creation of fine details, ensuring clear and legible codes, even on small or intricate packaging surfaces.

- Laser coding can be applied to a wide range of materials, including paper, cardboard, plastics, glass, metals, and more. This versatility makes it suitable for various packaging types and industries.

- Laser coding systems can be used for variable data printing, allowing for the inclusion of unique information on each package. This is useful for serialization, traceability, and anti-counterfeiting measures.

- Laser coding is considered environmentally friendly as it often requires no consumables like inks or solvents. It produces minimal waste and emissions, making it a cleaner and more sustainable technology.

Start With KDW

+86 13559233681(Wechat, Whatsapp)

No1, Anbian Rd, Torch High-Tech Zone (XiangAn), Xiamen, Fujian, China