A Beginner’s Guide to Liquid Pouch

It is typically made from materials such as plastic or flexible laminates, liquid pouches provide a convenient and efficient way to package a variety of liquids, including beverages, sauces, condiments, and cleaning products.

The types of Liquid Pouch

Liquid pouches come in a variety of formats to suit different liquid contents and use.

Liquid pouches are popular for their lightweight and space-saving design, making them suitable for both consumer and industrial applications.

- Stand-Up Pouches

Stand-up pouches with a flat bottom to stand upright on store shelves. Usually includes a spout for easy pouring. Widely used for products like liquid detergents, sauces, and beverages. - Spouted Pouches

Spouted pouches always with a built-in spout or nozzle, for easily controlled pouring or dispensing. They are popular for products like baby food, drinks, and liquid condiments. - Flat Pouches

Flat pouches, like 3-side-seal pouches, with a sealed top and bottom. They are versatile and used for a variety of liquids, including juices, energy drinks, traditional Chinese medicine, and water. - Bag in Box – BIB

BIB with an integrated spout for controlled pouring, also known as spout bags, which are used for bulk products like liquid detergents, oils, wine, milk, and beverages. - Sachets

Small, and single-use sachet packaging is often used for condiments, liquid sweeteners, and flavorings. They are convenient for on-the-go applications.

Choosing the right type of liquid pouch depends on the specific requirements of the liquid product, consumer preferences, and the intended use.

Each type offers unique features to address different packaging challenges and enhance the overall user experience.

The Best Material for Liquid Pouches

The choice of material for making liquid pouches is crucial to ensure product integrity, preservation, and user convenience.

When manufacturing liquid pouches, the ideal substance depends on certain criteria.

- Pouches containing beverages or foods demand materials that pose no risk to human health.

The typical material structure is PET/NY/PE.The outer PET layer provides good stiffness to show the customers’ brand on store shelves.NY layer protects the content from dropping.

- Liquid pouches for holding cleaning products, lotions, shampoos, and other liquids for household or personal use, widely made from NY/PE, NY/NY/PE, and PET/NY/PE.

Nylon film with anti-drop, and the double layer of NY suitable for heavy duty. - Medical bags necessitate components known to be non-reactive and sterile.

- For transporting liquids, the choice compound should withstand vibration and impact without leakage or rupture.

NY/PE&PE is the traditional material structure for liquid bulk packaging. The outer NY layer with excellent drop resistance, and the inner individual PE layer provides secondary protection. - Industrial shipping demands construction from tough, resilient materials that can withstand rigorous handling and loading/unloading.

Depending on what is being contained, liquid pouches differ in their design.

What Can be Contained in Liquid Packaging Pouch

Liquid packaging pouches are versatile and can be used to contain a wide range of liquid products, such as:

- Beverages: ready-to-eat soups, liquid broth…

- Soup and Broth: water, fruit juices, sports drinks, iced tea, coffee…

- Liquid Condiments: sachets for vinegar, soy sauce…

- Edible Oils: olive oil, vegetable oil, cooking oils, etc.

- Dairy Products: milk, yogurt drinks…

- Liquid Seasonings: liquid flavor enhancers, liquid broth or stock…

- Alcoholic Beverages: cocktails, wine (single servings)…

- Pharmaceuticals: liquid medications ( traditional Chinese medicine, cough syrups…

- Cleaning and Household Products: liquid detergents, fabric softeners, cleaning solutions…

- Cosmetic and Personal Care Products: shampoo and conditioner, liquid soap…

- Industrial and Chemical Liquids: lubricants, liquid fertilizers, and specialty chemicals.

The liquid packaging pouch is versatile and suitable for a diverse range of industries and applications.

The convenience, portability, and customizable features of liquid pouches contribute to their popularity in packaging various liquid products.

The Benefits of Liquid Pouch Packaging

Compared to traditional packaging options, liquid pouch packaging offers some benefits:

- Convenience:

Its lightweight and portable properties, make them easy to carry and transport. This reduces shipping costs and emissions also.They are particularly suitable for on-the-go consumption, consumers can enjoy liquids like beverages, and liquid condiments conveniently.

- Space-Efficient:

Compared to rigid containers such as bottles or cans, the flexible nature of liquid pouches allows them to be compressed, taking up less space during shipping and storage, and optimizing space utilization. - Cost-Effective:

Producing liquid pouches requires less plastic than bottles or cans. The packaging material itself is cheaper.Its lightweight nature reduces shipping costs.

The efficient use of materials and the ability to print graphics directly on the pouches reduce the cost compared to other packaging formats.

- Resealable:

The liquid pouches often have zippers, caps, or spouts that allow partial contents to be resealed for later use. - Low waste:

Liquid pouch packaging with spouts or nozzles facilitates controlled pouring or dispensing of liquids, minimizing spills and mess.Its shape closely matches liquid contents, minimizing air pockets and space. Less packaging is needed.

All these reduce the waste.

- Customizable:

Liquid packaging pouches come in various shapes and sizes, and offer ample space for branding and product information, allowing packaging to be tailored to specific products and volumes.They can be customized with eye-catching graphics, logos, or product descriptions, enhancing product visibility and attracting consumer attention on store shelves.

- Sustainability:

Many liquid pouches are designed to be eco-friendly. They often use less material compared to other packaging options, reducing waste generation.Liquid pouches made from recyclable or compostable materials help increase sustainability.

Liquid pouch packaging offers convenience, space efficiency, customization options, and product protection, making it a popular choice for a wide range of liquid products in various industries.

The Limitations of Liquid Pouch

While liquid pouches offer numerous advantages, they also have some weaknesses and limitations that should be considered.

- Puncture and Tear Sensitivity:

As liquid pouches lack rigid walls, they are vulnerable to punctures, tears, or other damage that could breach the packaging integrity. Careful handling during transportation and use is essential. - Less Perceived Premium Quality:

Some consumers may still perceive pouches as less premium than rigid bottles or jars for some markets and product types.Marketing is needed to change perceptions.

- Recycling availability:

While many liquid pouches are designed with environmental considerations in mind, there are still challenges related to recycling and waste management.

While liquid pouches have certain drawbacks, innovations in technology and materials research are addressing many challenges.

Manufacturers must prudently assess their individual needs and make informed decisions by weighing the unique benefits and constraints of this packaging solution.

What Makes Liquid Pouch Prices Different?

While liquid pouches offer numerous advantages, they also have some weaknesses and limitations that should be considered.

- Materials:

The type of material used, such as PET, nylon, or PE all affect costs.High-quality, specialized materials with enhanced barrier properties or sustainable features may incur higher costs.

- Printing and Branding:

More extensive use of printing, graphics, or specialized inks on the liquid pouch surfaces leads to higher cylinder fees. - Size:

As we know, the physical size and volume capacity of the liquid pouch contribute to the cost.Larger pouches generally cost more due to using more material. Custom sizes may also influence pricing.

- Features:

Liquid pouch with spout and cap, or specialized closures such as resealable zippers, or laser score for easy tear, require more complex manufacturing and may have higher production costs.Additional features that enhance user convenience or functionality increase the prices.

- Pouch Type and Design Complexity:

The type of liquid pouch and its complexity of design impact the production process and, consequently, the price.Stand-up pouches, spouted pouches, bag in box, and pouches with unique shapes may require specialized manufacturing equipment, affecting costs.

Intricate pouch shapes or custom designs demand more engineering work and cost more to produce.

- Quantity and Order Volume:

Unit costs per pouch decrease with higher order volumes due to efficiencies of scale in manufacturing. Bulk orders or higher quantities often lead to lower unit costs. - Environmental Considerations:

Liquid pouches designed with eco-friendly or sustainable materials may have different cost structures compared to traditional pouches.Sustainable packaging for liquid may include recyclability, biodegradability, or the use of renewable resources.

- Qthers:

Some other factors such as Shipping and Transportation, Lead Times, Brand and Manufacturer Reputation, and Regulatory Compliance that contribute to the price of liquid pouch.

Insights into these pricing determinants allows manufacturers and buyers to make informed decisions based on their specific requirements, budget constraints, and the desired features for their liquid pouch packaging.

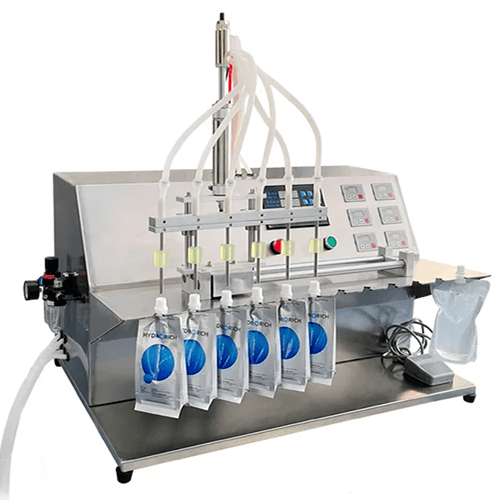

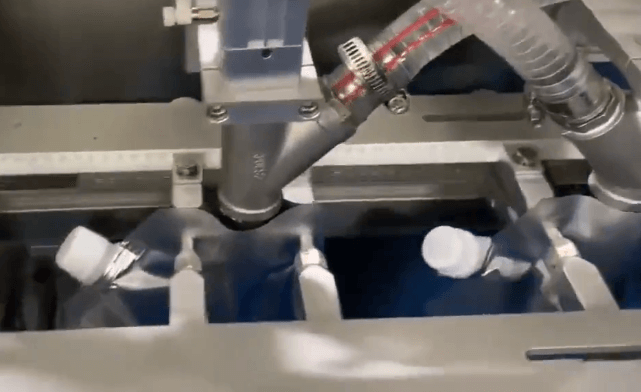

2 Ways to Fill Liquid Spout Bags

There are 2 ways to fill liquid spout bags:

- Filling Spout:

Liquid spout bags featuring a top spout typically allow the contents to be filled straight through that spout opening. The packaging manufacturer provides these spouted pouches with the spout cap left open/unclosed, ready for filling directly via the spout port.This enables a streamlined filling process where the liquid product can be deposited straight into the pouch interior through the conveniently accessible spout inlet, pre-opened by the packaging supplier.

- Filling Pouch:

The liquid spout pouch may arrive with the pour spout and cap still intact and fully assembled. There will be a void space or opening present at the top section of the pouch where your product can be added directly before heat sealing the void shut.This allows for a simple filling process where the contents are dispensed into the pre-formed void gap and then sealed closed immediately after using a thermal technique to fuse the void edges. The pre-attached spout and cap configuration streamlines loading without requiring additional capping steps after filling.

Eco-Friendly Pouches Packaging for Liquid at KDW

Eco-friendly packaging for liquids involves the use of sustainable materials and design practices to minimize environmental impact.

- Recyclable flexible liquid packaging:

Use packaging materials with recycled content, promoting the circular economy and reducing the demand for virgin materials.Opt for mono-material packaging, where the entire packaging structure is made from a single material. Such as Kanre™ HLE, and HBE, with single-layer material of polyethylene (PE).

This simplifies the recycling process and enhances the likelihood of successful recycling.

- Recyclable spouts:

Ensure that spouts, caps, and closures are also made from recyclable materials. Design them to be easily separable from the main packaging, facilitating recycling.Spouts and caps made from Post-Consumer Recycled (PCR) materials at Kinderway Packaging are a commendable step towards promoting an eco-friendly environment.

Incorporating PCR materials into spouts and caps aligns with sustainable practices and contributes to various environmental benefits.

- Packaging for liquid products:

- Explore reusable packaging solutions for liquids. Pouches designed for multiple uses can significantly reduce overall packaging waste.

- Design packaging that allows for easy refilling. Refillable options reduce the need for new packaging and contribute to waste reduction.

- Consider innovative packaging formats that use less material or novel materials. Examples include edible packaging, plant-based pouches, or dissolvable packaging.

Start With KDW

+86 13559233681(Wechat, Whatsapp)

No1, Anbian Rd, Torch High-Tech Zone (XiangAn), Xiamen, Fujian, China