Mono Material Packaging at KDW Help Your Sustainablity

What is Mono Material Packaging?

Mono material packaging means packaging made from only a single type of material, usually a single plastic or polymer. This is different from traditional multilayer packaging that combines different materials.

From an environmental perspective, mono material packaging is generally better because it is simpler to recycle. However, multilayer packaging may have advantages in some cases.

Why Mono-Material Packaging?

Mono-material packaging aims to improve recyclability, reduce environmental impact, and simplify the recycling process by using a uniform material that can be easily recycled.

This approach encourages the recycling of packaging materials and is consistent with sustainability goals by promoting a more circular and resource-efficient economy.

- Recyclable

Packaging made from a single material, single layer is much easier to recycle than multi-material and multi-layer packaging. The different materials in multi-layer packaging need to be separated during complex recycling.Mono material packaging uses just one type of material rather than different materials combined. This makes the packaging much easier to recycle. When items are made of just one material, it’s simpler to separate that material from other waste for recycling.

- Sustainability

Mono-material packaging produces less waste during manufacturing. It also allows for higher rates of recycled content to be used in new packaging. This supports circular economy goals.The single material can then be reprocessed and reused to make new packaging or other products. This keeps resources circulating in the economy. It reduces the amount of material that becomes waste.

Using one material also means less complexity during recycling. There’s no need to separate different components. This lowers the costs and effort of recycling processes. It makes it more efficient to get materials back into new production cycles.

- Easy of Sorting

It’s simpler to sort and collect mono material packaging for recycling since it doesn’t need to be separated which improves the efficiency of waste management systems, and lowers recycling costs.This is especially important in regions with advanced recycling infrastructure.

- Reprocessing

The single material can be efficiently reprocessed and reused to make new packaging and products without additional separation steps. - Waste Reduction

Mono-material packaging helps reduce packaging waste.

The only one material mono-packaging creates less waste during manufacturing compared to packaging with multiple materials.The simple structure of mono-packaging also makes it easier to manage in our waste collection systems. There is no need to separate different materials, which would otherwise complicate recycling.

This simplicity encourages more consumer participation in recycling. It’s easier for people to recycle packaging when they don’t have to worry about separating materials. They know everything can go in the same bin.

More recycling means less packaging ends up in landfills or as litter. When materials are recycled instead of thrown out, it reduces the overall amount of waste.

The single material can also be efficiently recycled and remade into new packaging or products. This keeps resources in use longer rather than becoming waste.

- Regulatory Compliance

Some places now have rules about packaging recycling and some rules encourage packaging to be easier to recycle.Companies that choose mono-packaging show they care about sustainability. Sustainability means using resources carefully so future generations have enough too.

Mono-material packaging makes it simple for companies to meet new recycling requirements.

- Consumer Perception

More and more people now care about helping the environment.Packaging with only one material fits with what people prefer. It’s easy to recycle and reuse materials instead of throwing them out.

Mono-material packaging corresponds with this growing pattern/tendency and can strengthen a brand’s image as an environmentally conscious company.

- Innovation and Advancements

New mono-materials are being made with stronger barriers against things like air and moisture. This allows more products to use packaging with just one material.As science expands what mono-materials can do, more products will have packaging options that are easy to recycle.

- Cost-Efficiency

Using single material for packaging can sometimes cut down the cost and save money. It makes production and recycling easier and cheaper.Recycling is less costly when there’s no need to separate materials. Collection and reprocessing are more straightforward too.

Simpler packaging means a simpler supply system to get materials.

Going with mono-material packaging embodies a prudent strategic choice balancing ecological issues, helping recycling programs, and harmonizing with spreading the need for eco-friendly, responsible packaging remedies. It denotes the observance of a more circular, environmentally sympathetic paradigm for packaging formation and fabrication.

Mono Material Flexible Packaging at KDW

No substance tested by recycling plants introduces as much complexity as PLASTIC, due to the difficulty of telling one plastic apart from another.

The popular plastics for flexible packaging, such as Polyethylene terephthalate (PET), Nylon, Aluminum foil are so difficult to depart from multi-layer lamination plastic films that cannot be mechanically recycled.

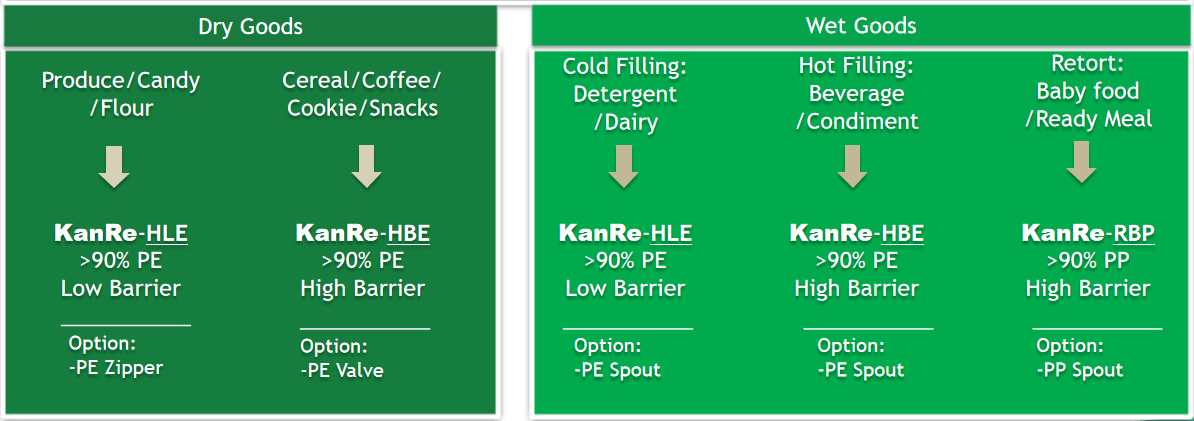

At KDW, our research divisions have studied mono-polypropylene and mono-polyethylene sole material alternatives and their ecological benefits. And have applied our own brand KanRe™.

- KanRe™ HBE – Hotfill grade high barrier PE, a recyclable film that is composited from the polyethylene family, which provides good moisture and gas protection and extends the shelf life of products that are packed. It can be applied to products such as beverages,

condiments. - KanRe™ HLE – Hotfill grade PE, a recyclable film that is composited from the polyethylene family, can be applied to both light and heavy-weight products in different packaging formats, such as reel stock and pre-made pouches.

- KanRe™ GBP – General high barrier PP, a recyclable film that is composited from the polypropylene family, provides good moisture and gas protection and extends the shelf life of products that are packed. It can be applied to products such as dry food, condiments.

- KanRe™ GLP -General PP

- KanRe™ HBP -Hotfill grade high barrier PP

- KanRe™ RBP – Retort high barrier PP

- KanRe™ HBO – Hotfill grade high barrier PE&PP, a recyclable film that composited from polyolefin family

For more properties, please refer to our sustainable packaging.

The Applications of Mono Material Packaging

Mono material pouch has a diverse range of applications across various industries due to its sustainable and recyclable nature.

- Food Packaging:

- Snack Bags: including chips, nuts, dried fruits, etc.

- Dry Goods Packaging: such as rice, pasta, and cereal.

- Fresh Produce: fresh fruits and vegetables, etc.

- Beverage Packaging:

- Single-Use beverage pouches: used for convenient and lightweight pouch packaging for beverages.

- Liquid packaging: mono-materials with enhanced barrier properties are suitable for packaging liquids like juices and sauces.

- Confectionery Packaging:

- Candy and Chocolate Wrappers: used for individual candies and chocolate bars.

- Personal Care Products:

- Shampoo and Conditioner Sachets: used for single-use sachets of personal care products.

- Soap Wrappers: soap bars and other personal care items.

- Pharmaceuticals and Healthcare:

- Medication Pouches: used for individual dose packaging of medications.

- Pet Products Packaging:

- Pet Food Packaging: such as pet food, treats, and related products.

- Household and Cleaning Products:

- Wipes Packaging: wet wipes and cleaning wipes.

- Detergent Pods: single-use detergent pods.

- Dishwashing powder

- Custom Packaging Solutions:

- Specialized Applications: Mono-material packaging can be tailored to specific product requirements, providing custom solutions for unique items.

Start With KDW

+86 13559233681(Wechat, Whatsapp)

No1, Anbian Rd, Torch High-Tech Zone (XiangAn), Xiamen, Fujian, China