Refill Pouches: Everything You Need to Know

What is Refill Pouch?

Refill pouches are packaging solutions designed to provide a convenient and eco-friendly way to replenish products without the need to purchase new containers each time. They are commonly used for various consumer goods such as food, beverages, cleaning products, personal care items, and more.

The refill pouches are becoming more and more popular in daily life. Especially in household and personal care products. Such as cosmetics, shampoo, body wash, and washing-up liquid.

The Benefits of Refill Pouches

The primary purpose of refill pouches is to reduce packaging waste and promote sustainability. By reusing the original container and only replacing the contents, consumers can minimize their environmental impact by reducing the consumption of single-use packaging. Refill pouches are often designed to be space-efficient, taking up less storage and transportation space compared to traditional packaging formats like bottles or cans.

- Cost savings: Refill pouches are often priced lower than fully packaged products. Compared to buying new containers each time, the refill pouches can save more money.

- Convenience: Refill pouches are designed for easy and mess-free refilling. They typically feature user-friendly resealable closures or dispensing mechanisms, making it convenient to refill containers without spills or waste.

- Space efficiency: Refill pouches are typically more space-efficient than traditional packaging formats. They occupy less storage space in your home or during transportation, making them ideal for smaller living spaces or when traveling.

- Reduced waste: By reusing containers and refilling them with products, refill pouches help minimize packaging waste. This contributes to overall waste reduction and decreases the environmental impact associated with single-use packaging.

- Brand loyalty and trust: Companies that offer refill pouches demonstrate their commitment to sustainability and environmental responsibility. By choosing brands that provide refill options, consumers can support these initiatives and develop trust and loyalty towards companies that prioritize sustainable practices.

Refill pouches offer a convenient, cost-effective, and environmentally friendly way to purchase and use products. They align with the growing consumer demand for sustainable options and contribute to a more circular economy.

Refill Packaging VS Plastic Rigid Bottles

When faced with the decision between purchasing multiple bottles of laundry detergent, shower gel, and other heavy-duty cleaning products versus opting for single bottles with refill options, it is important to approach the choice from an environmental standpoint and select packaging methods that promote sustainability.

Considering the environmental perspective, it is advisable to prioritize packaging formats that minimize waste and resource consumption. In this context, choosing refillable packaging options can be more favorable. By purchasing a single bottle and subsequently refilling it with larger quantities of the product, we can significantly reduce the amount of plastic waste generated. Refill packaging often utilizes less plastic material overall compared to multiple individual bottles, thereby reducing environmental impact and contributing to sustainable development.

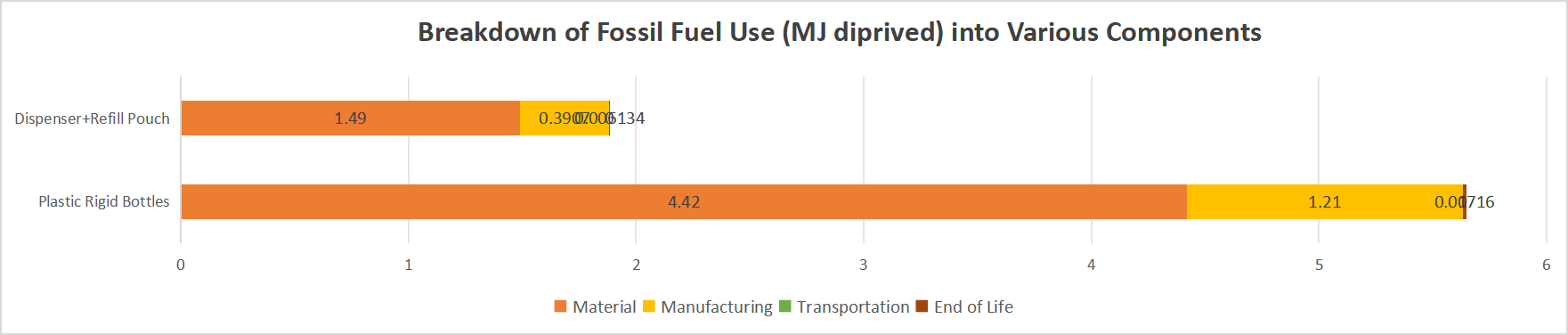

Fossil Fuel Use (MJ deprived)

Let’s see the fossil fuel use data comparison of the 5 pcs of 250ml plastic rigid bottles vs 1 pcs of 250ml dispenser with 1 pcs of 1000ml refill pouch. And which one with higher environmental cost.

The total quantity of fossil fuel consumed throughout the life cycle reported in megajoules (MJ) equivalents deprived. This calculation uses the IMPACT World+ method and assumes fossil resources are mainly used for energy purposes. Fossil fuels include coal, petroleum, and natural gas. Inputs for nuclear fuel such as uranium are accounted for in the MINERAL CONSUMPTION metric.

| Plastic Rigid Bottles | Material 4.42 (78.25%) | Mamufacturing 1.21 (21.44%) | Transportation 0 (0%) | End of Life 0.01716 (0.3038%) | Total 5.65 |

| Dispenser+Refill Pouch | Material 1.49 (78.95%) | Mamufacturing 0.3907 (20.72%) | Transportation 0 (0%) | End of Life 0.006134 (0.3254%) | Total 1.89 |

Upon comparing the data, it becomes evident that the fossil fuel consumption associated with 5x250ml plastic rigid bottles is significantly higher than that of a dispenser with refill pouches. The environmental impact of refill pouches is considerably lower.

The production and transportation of multiple plastic bottles require a substantial amount of fossil fuels. Each bottle necessitates the extraction, refining, and processing of raw materials, resulting in increased energy consumption and emissions. Additionally, the transportation of these bottles to various locations further contributes to fossil fuel usage and associated carbon emissions.

In contrast, using a dispenser with refill pouches offers several environmental benefits. Refill pouches generally require less plastic material in their production, reducing the overall environmental footprint. The transportation of refill pouches is more efficient due to their compact and lightweight design, resulting in lower fuel consumption and emissions during shipment.

Moreover, opting for refill pouches encourages a reduction in single-use plastic waste. By refilling the dispenser, the need for additional plastic bottles is eliminated, leading to a significant decrease in plastic waste generation and subsequent environmental pollution.

Considering these factors, it is evident that choosing a dispenser with refill pouches has a positive impact on the environment by reducing fossil fuel consumption, lowering carbon emissions, and mitigating plastic waste. Embracing such sustainable packaging solutions aligns with the principles of environmental conservation and sustainable development.

The Structure Materials for Refill Pouches

Refill pouches are typically made using a combination of different materials to achieve the desired properties such as flexibility, durability, and barrier protection.

- Traditional Structure: NY/PE

Polyethylene-PE is commonly used as the primary material for refill pouches.

PE film offers versatility, strength, and moisture resistance, and is widely used for packaging as sealant layer.

Nylon is known for its exceptional strength, durability, and barrier properties to protect the liquid product from drop. - Common Structure: TPE/NY/PE

For heavy-duty, 3 layers of laminated film will be considered, that is TPE/NY/PE.

TPE is polyester film or polyethylene terephthalate film that possesses excellent mechanical, optical, and barrier properties, making it suitable for various applications in packaging for the outer printing layer.

Depending on the application, various materials can be used between the outer and sealant layers. Nylon film is commonly used.

PET/NY/PE is the common structure for refill pouches with high performance. - Recyclable Structure: KanRe HBE or HLE

Traditional multilayer refill pouches are not optimized for sustainable recycling.

Sustainable packaging is the future, KanRe™ mono-material developed proprietary by KDW actively supports the brand’s sustainability initiatives. KanRe HBE and KanRe HLE are widely used for the refill pouches.

KanRe™ HBE KanRe™ HLE Hot fill, high barrier polyethylene – PE film Hot fill polyethylene – PE film - Good gas, oxygen barrier

- Good stiffness properties

- Suitable for food packaging, cold filling, hot filling, pasteurization, HPP

- Good stiffness properties

- Suitable for liquid and food packaging

Refill Packaging Applications at KDW

Refill pouches have gained popularity in various market applications due to their convenience, sustainability, and cost-effectiveness. Here are some market applications at KDW:

- Food and Beverage:

Refill pouches provide a convenient way to refill existing containers or dispensers, reducing packaging waste and offering cost savings to both manufacturers and consumers. They are extensively used in the food and beverage industry for products such as sauces, condiments, oils, and beverages. It is also reusable, you can tightly seal the remaining portions with the cap, ensuring their preservation for subsequent utilization. - Personal Care and Cosmetics:

Refill pouches are increasingly being adopted in the personal care and cosmetics industry. Products such as shampoos, conditioners, body lotions, hand soaps, and skincare items can be refilled using pouches, allowing consumers to reuse their existing containers. This reduces plastic waste and promotes sustainable packaging practices.

Refill pouches are also utilized in the pet care industry for items such as pet shampoos, conditioners, and cleaning solutions. Pet owners can easily refill their existing bottles or dispensers, minimizing plastic waste and contributing to sustainable practices. - Cleaning and Household Products:

Cleaning and household products such as laundry detergents, dishwashing liquids, surface cleaners, and air fresheners are usually chosen refill pouches. By offering refill options, manufacturers can reduce the amount of single-use plastic packaging and provide a more eco-friendly solution for consumers. - Health and Personal Hygiene:

Refill pouches are employed in the health and personal hygiene sector for products like hand sanitizers, antibacterial soaps, and lotions. These pouches allow for easy refilling of smaller, portable containers, promoting hygiene practices while reducing packaging waste.

The refill pouch market continues to expand as more industries recognize the benefits of sustainable packaging solutions. By offering refill options, companies can align with consumer demand for environmentally friendly choices and contribute to waste reduction efforts.

Start With KDW

+86 13559233681(Wechat, Whatsapp)

No1, Anbian Rd, Torch High-Tech Zone (XiangAn), Xiamen, Fujian, China

Refill pouches are increasingly being adopted in the personal care and cosmetics industry. Products such as shampoos, conditioners, body lotions, hand soaps, and skincare items can be refilled using pouches, allowing consumers to reuse their existing containers. This reduces plastic waste and promotes sustainable packaging practices.

Refill pouches are increasingly being adopted in the personal care and cosmetics industry. Products such as shampoos, conditioners, body lotions, hand soaps, and skincare items can be refilled using pouches, allowing consumers to reuse their existing containers. This reduces plastic waste and promotes sustainable packaging practices.